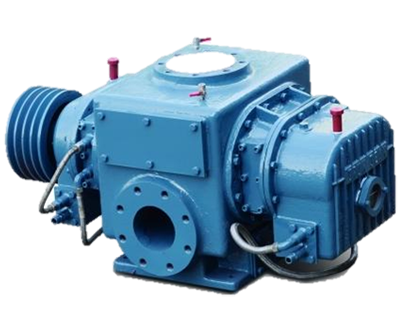

TH Series - Roots Blower

Minimal Vibration and Lowest Noise

AMCL in collaboration with world leaders Trundean Industrial Machinery Co. Ltd of Taiwan, brings to India advanced technology to manufacture the most rugged and efficient industrial blowers. AMCL / Trundean offers a wide range of Blowers for industrial usages which includes Three lobe Root Blowers, Ring Type / Centrifugal Blowers, Magnetic Drive pumps etc.

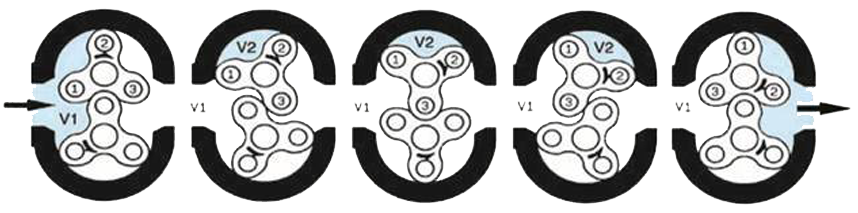

Principle of Operation

There are two rotors in the compartment of the blower body, when the rotors operate in the opposite direction, they suck air in to balance the pressure created due to the volume V 1 change on the inlet size. And the air of the volume V2 will be sent out through the discharge side and the high pressure will be created through the discharge There is no need to supply any lubrication between two rotors because of the existing clearance between them which gives no worry about the possibility of friction. The blower runs well at high speed and produces clean air; it is also applied to vacuum purpose. and technical expertise. These ARJ Series high performance Blowers employ three lobe rotor designs which reduce noise and vibration level. This World Class mechanical marvel is indigenously manufactured at AMCL’s state –of-the-art plant at Butibori near Nagpur. These Blowers are working in different industries in India and abroad at utmost satisfaction of our customers due to excellent product performance and our after sales parts and service support.

Features and Benefits

Robust Design

Higher Blower efficiency

Ensures oil free air and safe operation

Low noise & minimum vibration

Ease of Maintenance & Replacement

TH Type

- Pressure : 0 - 6000 mmAq

- Power : 1 - 300 HP

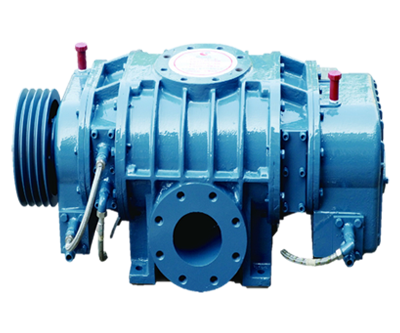

THS Type

- Pressure : 0 - 8000mmAq

- Power : 10 - 250 HP

THW Type

- Pressure : 0 - 10000 mmAq

- Power : 15 - 300 HP