Transit Mixers and Bulkers

AMCL started production of transit mixers in technical collaboration with M/s. ShinMaywa Industries Ltd. Japan.

M/s ShinMaywa has long experience in manufacture of special purpose vehicles as per the international design. This is a great combination of Advance technology and a User Friendly Design which makes it special. The Mixing drum and blades which are vital parts of mixer are made from special quality steel and the drum speed is suitably selected to keep the quality of the ready mix concrete intact. The drum diameter is so deigned to give high volumetric capacity and pay load. The power train components are of most reputed and proven to give long life and trouble free performance.

Drum and Blades

The mixing drum is made of high abrasion resistant steel and blades of high abrasion resistant alloy steel to mix any type of ready mix concrete and to discharge it smoothly.

Features:

- Detachable triangle blades for good mixing performance.

- Option of one or two holes in the drum for easy cleaning work.

Hopper

Wide mouth hopper is specially designed to receive sticky ready mix concrete in large quantities with ease.

Hopper steps and Handrail

Layout of hopper steps and handrails are made user friendly for standing at ease for cleaning purpose ensuring better safety. Side steps made from rust proof steel are attached as standard equipment with stripes for anti-slip and fender for easy movement.

Scoop

Scoop is made from Abrasion resistant steel for durability and weight reduction instead of traditional MS thick plates with liners.

Chute

Easy to use chute made of high abrasion resistant steel is provided with two options of detachable chute extension for smooth flow of discharge in concrete pump hopper or direct discharge.

Technical Specifications

Nominal Capacity |

6 m3 |

Geometric Volume |

10.35 m3 |

Filling Ratio |

58 % |

Rotation Speed |

0 - 15 rpm |

Water Pump Output Pressure |

150 lmp / 3 bar |

Water Tank Capacity |

600 ltr |

Driven By |

|

Separate Engine |

HA - 494 (KOEL) mm |

Required Power |

254 / 153 / 47 rpm |

Dimensions |

|

Max. Length (L) |

5923 mm |

Drum Inclination |

16 deg |

Max. Height (H) |

2500 mm |

Max. Width |

2530 mm |

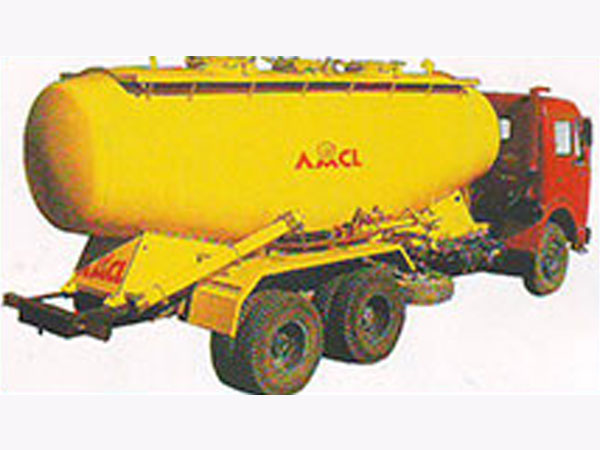

Bulk Transporter

AMCL Air Slide type bulk transporters are specially designed for transporting and pneumatically discharging granular as well as powdered materials and have a superior discharge performance with minimum residue. They are suitable for a wide range of material like:

- Fly ash

- Cement

- Moulding sand

- Calcium carbonate

- Talc

- Food Grains

- Synthetic Resin

- Quick Lime

Particle size up to 5mm dia can be effectively handled. The AMCL bulk transporters are available for mounting on rigid chassis and also as Semi Trailer with varied bulk transporter capacities. Customized bulk transporting solutions are offered to suit specific industry needs. To suit different industrial applications, the AMCL bulk transporters are available in several sizes.

Slide Bulk Transporters

Applications:

- Cement

- Alumina

- Talc

- Fly Ash

- Food Grains

- Powdered Lime

Features:

- Bulk Handling

- Low Maintenance

- Low Power Consumption

- Tampler Proof

- Enviro Friendly

- Low Handling Losses

Models

Chassi Mounted - 30 m3 , 34 m3

Semi-Triler type - 38 m3 , 45 m3, 50 m3 , 56 m3

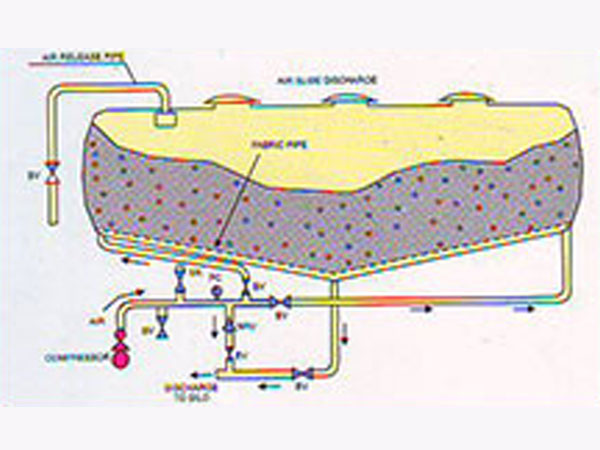

Principle of Operation

- Loading: Material bulk loading is done through the man holes provided on the top of the tank. The man holes are secured air-tight after loading for transportation.

- Unloading: Compressed air at 1.95 kg/cm' available at the unloading station is required to agitate the tank through perforated fabric pipes provided at the bottom of the tank and also in the discharge piping (fig i). Due to the agitated state of the material, it is discharged through the outlet port into the receiving station. The discharge condition is shown in the schematic drawing.

Features of AMCL Bulk Transporters

- Eliminates need of packing in bags and expenses thereof.

- Transport in closed tank assures quality and quantity of material.

- No environment pollution.

- Easy operation by single operator.

- Near 100% evacuation to heights up to 45m. Discharge rates depending on material transported.

- Proven design, light weight tank gives low tare weight and better fuel efficiency.

- Sand blasting Et a special anti-corrosive paint for long life.

- Reputed make of accessories for long trouble free operation.