Tyre Building Machine

AMCL's complete range of tyre building machines are manufactured to internationally accepted designs and have further been specifically matched to suit the Indian tyre Industry, thus ensuring consistently high productivity of quality tyres. These machines feature different controls such as Manual, Semi-Automatic with varying degrees of sophistication and details. Additionally, safety features built into the design make the operations free from unintended errors.

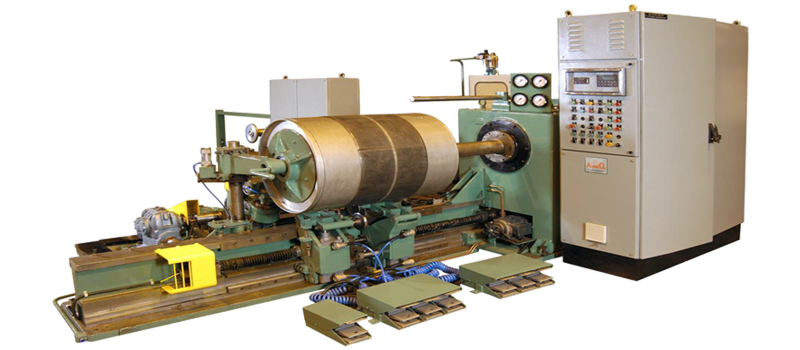

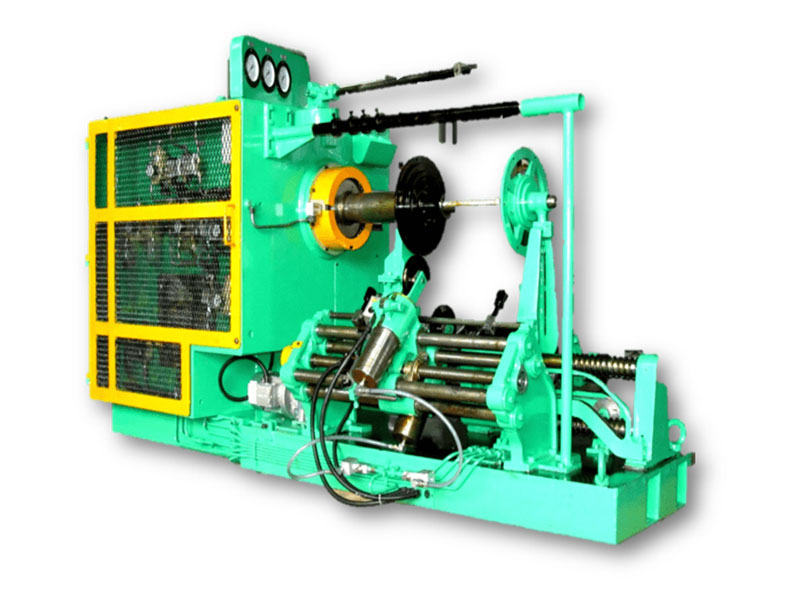

Tyre Building Machine for Truck & LCV RB2022

Exclusive Features

- Incorporates state of the art PLC Controls.

- Complete Tyre Building cycle programmed.

- Position control through pulse encoder in conjunction with PLC ensuring productivity, precise control, improved quality and easy setting.

- In built safety features built into design makes operation free from unintended errors.

- User friendly interface.

Machine Features

- Sturdy and Robust Construction

- Lower Power Consumption

- Least Maintenance

- Operationally Safe

Constructional Features

- Head Stock Assembly with hardened and tempered drum shaft, quill shaft, zero speed drum collapse mechanism.

- Centre Base Assembly is aligned and fitted to head stock assembly, ply and tread stitcher assembly installed in front and bead stitcher assembly at rear side.

- Bead Setter Assembly performs 'Bead Set' & 'Pull Out' operation by combination of air cylinder.

- Spring Ring Ply Pull out assembly is provided for automatic ply pull out for ply turn up operation.

- Triaxial Stitcher Assembly with dual tool capable in moving in all 3 axis performs turn down, turn up, bead stitching, bead toe stitching & tyre stripping operation.

- Ply & Tread Stitcher performs ply/band stitch, tread stitch and side wall stitch operation by a double acting pneumatic cylinder in combination with traverse movement by an independent motor.

- Pneumatic Control Panel with reputed components.

- Control Panel with PLC for Auto Sequence Operation.

- Line Projectors.

Technical Data Sheet

Product Size |

Dual Bead Truck Tyres from 20"to 22"& Single Bead Tyres From 18" to 24 |

Type |

Ply/Band method of tyre building |

Drum Dia |

Minimum 625 mm to 705 mm Maximum |

Drum Shoulder Set |

381 mm to 737 mm 890 mm |

Drum Centre Height |

890 mm |

Max. Ply / Band Width |

1117 mm |

Max. Ply / Overhang (Each Side) |

288 mm |

Drum Centre Distance |

1220 mm |

Drum Shaft Speed |

254 / 153 / 47 rpm |

Main Drive Motor |

3 speed A.0 Motor, 3.7 / 2.2 / 0.42 KW, 950 / 570 / 165 rpm |

Ply / Tread Stitcher Motor |

1116 / 558 mm/min. (0.55/0.20 KW x 1380 / 660 rpm dual speed A.C.Motor with brake) |

Radial Motor |

0.55 KW x 900 rpm with brake(300/ min) |

Traverse Motor |

Dual Speed A.C. Motor 0.55 / 0.2 KW x 1380 / 660 rpm with brake (348 mm/min.) |

Rotary Motor |

A.C. Motor with VFD 1.0 KW x 1400 rpm (8.57 rpm or 51° 25'/ sec.) |

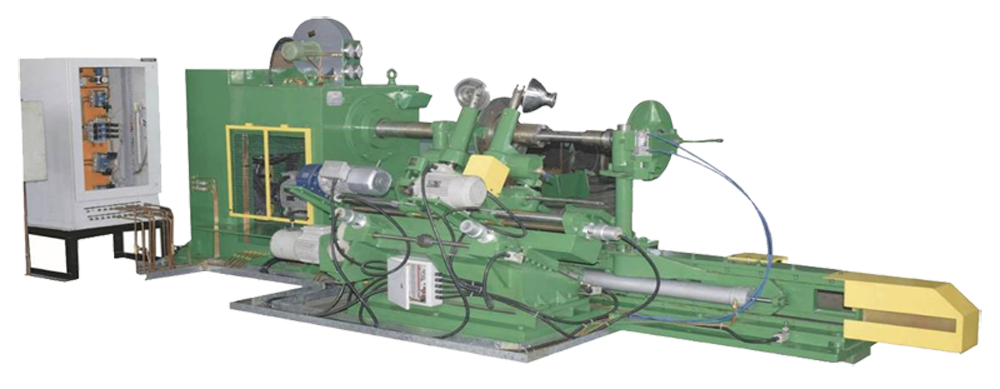

Dual Bead LCV Tyre Building Machine RB 1619

Exclusive Features

- First machine developed indigenously for heavy duty Dual Bead LCV Tyres.

- Robust Tri-axial Bead Stitcher Assembly.

- Reduced operator fatigue.

- Quick set up change over facilities during change of production program.

Constructional Features

- Head Stock Assembly with hardened and tempered drum shaft, quill shaft, zero speed drum collapse mechanism.

- Centre Base Assembly is aligned and fitted to head stock assembly, ply and tread stitcher assembly installed in front and bead stitcher assembly at rear side.

- Bead Setter Assembly performs 'Bead Set' & 'Pull Out' operation by combination of air cylinder.

- Spring Ring Ply Pull out assembly is provided for automatic ply pull out for ply turn up operation.

- Triaxial Stitcher Assembly with dual tool capable in moving in all 3 axis performs turn down, turn up, bead stitching, bead toe stitching & tyre stripping operation.

- Ply &Tread Stitcher performs ply/band stitch, tread stitch and side wall stitch operation by a double acting pneumatic cylinder in combination with traverse movement by an independent motor.

- Pneumatic Control Panel with reputed components.

- Control Panel with PLC for Auto Sequence Operation.

- Line Projectors.

Technical Data Sheet

Product Size |

Dual Bead LCV Tyres. |

Type |

Ply/Band method of tyre building |

Drum Dia |

495 mm |

Drum Shoulder Set |

370 - 620mm Maximum |

Max. Ply / Overhang |

175 mm |

Drum Centre Height |

870 mm |

Max. Ply / Band Width |

965 mm |

Drum Centre Distance |

1075 mm |

Drum Shaft Speed |

335 / 224 / 56 rpm, 3 speed A.C Motor, 3.7 / 2.2 / 0.42 KW, 950 / 570 / 165 rpm |

Ply / Tread Stitcher Motor |

798 mm/min. (0.55 KW, 133 rpm Geared Motor suitable for VFD) |

Radial Motor |

0.37 KW x 1500 rpm A.C. Motor with brake (250 mm/min.) |

Traverse Motor |

0.37 KW x 114 rpm geared motor with brake (342 mm/min) |

Rotary Motor |

0.55 KW x 1000 rpm A.C. Motor with brake and VFD |

Product Size |

24” to 32” Single bead |

Type |

Ply/Band method of tyre building |

Drum Dia |

495 mm |

Drum width |

700 mm-1700 mm |

Max. band/ Ply Overhang |

450 mm on either side |

Drum Centre Height |

1100 mm |

Max. Ply / Band Width |

2600 mm |

Drum Shaft Speed |

254 rpm variable through AC Motor with VFD |

Stitcher Motors |

All special duty |

Main Motor Drive motor |

11 KW |

Radial Motor |

AC TEFC 1.5 KW 1500 RPM with brake. |

Traverse Motor |

AC 0.75 KW, 1400 RPM, geared motor with brake, O/p RPM-98. |

Contour |

AC 1.5 KW base speed 1500 RPM. |

Ply / Tread stitcher Motor |

0.55 KWx1500 RPM with brake |

Product Size |

24” to 32” Single bead |

Type |

Ply/Band method of tyre building |

Drum Dia |

670mm-840 mm |

Drum width |

800mm-1200 mm |

Max. band/ Ply Overhang |

250 mm on either side |

Drum Centre Height |

1100 mm |

Max. Ply / Band Width |

1800 mm |

Drum Shaft Speed |

254 rpm variable through AC Motor with VFD |

Stitcher Motors |

All special duty |

Main Motor Drive motor |

7.5 KW |

Radial Motor |

AC TEFC 0.5 kW 1500 RPM with brake. |

Traverse Motor |

AC 0.55 kW, geared motor with brake |

Contour Motor |

AC 0.55 kW base speed 1500 RPM with VFD & Brake |

Ply / Tread stitcher Motor |

Dual Speed AC Motor special duty 0.7 / 0.5 kW 1500 / 750 RPM. |

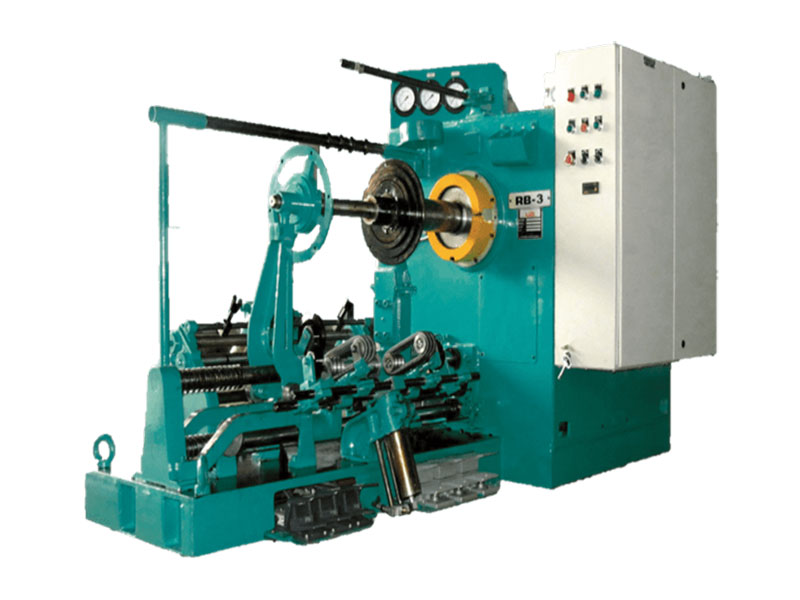

Truck Tyre Building Machine RB-5/1 TR

Exclusive Features RB – 5/1 TR

Ply Tread Stitcher

- Completely Independent.

- Three pressure stitching provided.

- Special stitcher roller design ensures zero air traps at the center.

- Lead screw is provided with split nut & angular contact anti-friction deep groove ball bearing.

- Sturdy design with stitcher rollers supported with double fork link mechanism to provide rigidity.

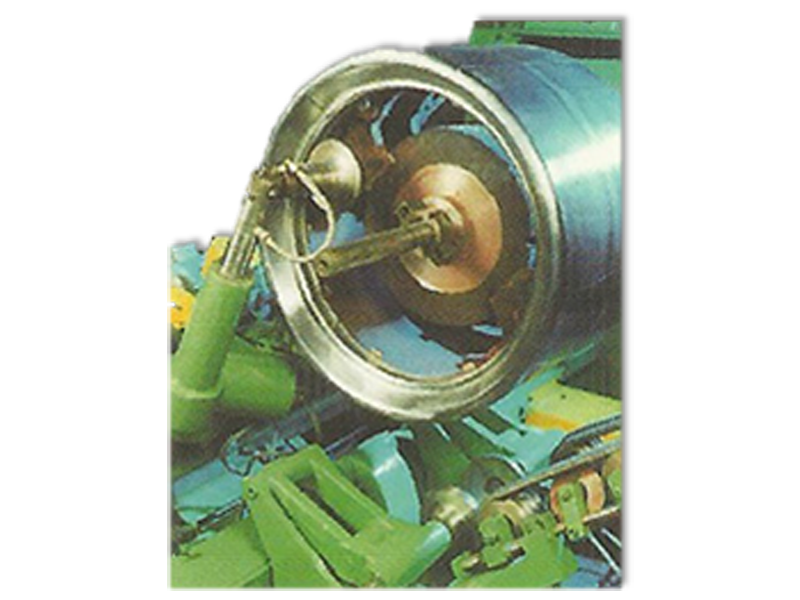

Tri- Axial Stitcher

- With dual tool capable of moving in all three axis with independent drive for each axis.

- Capable of performing turn down, contour stitching, bead stitching, toe stitching and tyre stripping.

- Dual stitching tool contacts the tyre under controlled pressure by pivoting about the rigid center line tool support post.

- Radial strip out operation incorporated.

Optional Items

- Tyre Building Drum, Servicer, Ply cups.

- Tractor Rear and OTR Tyre Building Machines of similar design features are also manufactured.

- Specifications to suit customized designs requirements can be incorporated.

Technical Data Sheet

Product Size |

8.25-20 to 12.00-24 |

Type |

Band Method or Single Ply Method |

Max Band Overhang (mm) |

250 |

Max Bandwidth (mm) |

1400 |

Drum Diameter (mm) |

530 to 860 |

Drum Width (mm) |

450 to 750 |

Drum Centre Height (mm) |

1050 |

Drum Shaft Speed (rpm) |

3 Speed 254 / 153 / 47 |

Main Drive Motor |

3 speed AC/DC Fan Cooled with Thermal Protection. |

Ply / Tread Stitcher Motor |

0.7 KW - 1500 RPM DC Motor with Two Speed Setting Range |

Radial Motor |

AC - TEFC 0.55 kW 1500 rpm with Brake |

Traverse Motor |

AC - 0.55 kW Geared Motor with brake |

Contour Motor |

DC - TEFC 0.55 kW Two Speed with Lower Speed Infinitely Variable |

Main Shaft Drive |

6 kW Special Duty |

- Models with Manual, Semi – Automatic control

- Low Power Consumption

- Least Maintenance

- Operationally Safe

- In built safety features built into design makes operation free from unintended errors

- Auto Ply/ Tread Stitcher with VFD

- Bead Setter Assembly

- Zero Speed Drum Collapse Mechanism

- Hand Tools for Ply Turn Up & Turn Down

- Laser Light for Centre Marking

Model Number |

RB - 1 |

RB - 3 |

RB - 265 |

Product Size (Bead) |

8” to 13” | 12” to 19” | 24” to 30” |

Maximum Drum Diameter (mm) |

400 | 600 | 863 |

Maximum Drum Width (mm) |

400 | 600 | 1200 |

Maximum Ply over Hang (mm) |

100 | 140 | 254 |

Drum Center Height (mm) |

900 | 850 | 940 |

Drum Shaft Speeds (rpm) |

240/60 | 180/45 | 250 |

Stitcher Motor Rating (Kw) |

0.37 | 0.37 | 1.5 |