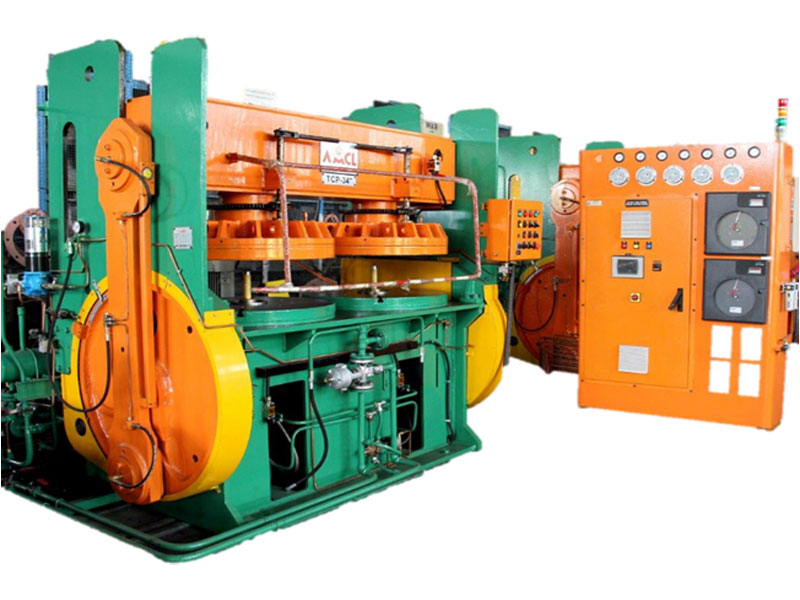

Tyre Curing Presses

AMCL’s AUBO range of Bag-O- Matic type tyre curing presses meet the curing needs of scooter, motor cycle, mopeds, passenger car, LCV, ADV, truck, tractor & OTR Tyres.

- AMCL’s AUBO range of Bag-O-Matic type curing presses meet the curing needs of scooter, motorcycle, mopeds, passenger car, LCV, ADV, truck, tractor & OTR tyres.

- For truck & OTR sizes, presses are available both in dome and platen design.

- Our CUREX-B Tyre Curing Presses are a result of extensive R&D, proven design and rugged construction.

- Reliable operation with minimum maintenance.

- Entire operation of green tyre loading, alignment, curing, stripping & tyre unloading is done with precision in short time.

- Resulting in Enhance productivity.

Platen Type Presses

Dome Type Presses

Technical Data of Mechanical Tyre Curing Press

Model |

Bead Dia. |

Applicable Tyre |

Maximum Closing Force/Cavity (Tons) |

Platen Diameter (mm) |

Mould Accommodation Height |

Max Tyre Internal Pressure kg/cm2 |

|

| Max (mm) | Min (mm) | ||||||

TCP 24” |

8” – 12” | Scooter | 50 | 630 | 240 | 120 | 21 |

TCP 30” |

8” – 12” | Scooter & Motorcycle | 70 | 805 | 250 | 120 | 21 |

TCP 36” |

8” – 19” | Scooter & Motorcycle | 75 | 915 | 260 | 120 | 21 |

TCP 42” |

16” – 19” | Passenger Cars & LCV | 140 | 1010 | 330 | 120 | 28 |

TCP 45” |

17” – 19” | Passenger Cars & LCV | 160 | 1070 | 460 | 200 | 28 |

Dome Presses (Truck) |

|||||||

TCP 55” |

15” – 22.5” | Bus & Truck | 295 | 1310 | 445 | 241 | 7 Kg/Cm2 |

TCP 65.5” |

17” – 24.5” | Bus, Truck & Tractor Rear | 453 | 1575 | 635 | 254 | 7 Kg/Cm2 |

Exclusive Features

- Low operating cost due to optimized Machine Design, Hydraulics & Curing Circuit Design.

- High quality and high precision.

- Data recording & retrieval arrangement.

- Equipped with all the required safety features including safety switch & emergency stop arrangement.

- Robust, reliable and durable.

- Easy to install and maintain due to simple design & standardized components.

- Environment friendly operation.

Basic Machine

The press is assembled completely with Machine Frame, Centre Mechanism including Bladder Cylinder & Ejector Cylinder, Heating Platens, Hydraulic Power Unit along with Control Valve Blocks, Interconnecting piping, Heating & Curing Circuit, Safety Arrangements, Operation & Instrumentation Panels etc.

View from Operator’s Side

View from Back Side

Technical Data Sheet of Hydraulic Tyre Curing Press

Type |

14” X 36” |

16” X 42” |

22” X 60” |

26” X 84” |

| Working diameter of Rolls (mm) | 356 | 406 | 560 | 560 |

| Working lengths of rolls (mm) | 702 | 1067 | 1524 | 2134 |

| Working linear speed of front roll (RPM) | 19.0 | 17.97 | 12.78 | 10.75 |

| Max gap (mm) | 12 | 12 | 12 | 12 |

| Capacity per. Batch (kg) | 35 | 60 | 90 | 250 |

| Driving motor power (kw) | 30 | 37 | 100 | 110 |

| Overall Length (mm) | 3456 | 4250 | 6120 | 8134 |

| Overall Height (mm) | 1425 | 1850 | 2280 | 3124 |

| Overall Width (mm) | 1610 | 1870 | 2000 | 2184 |

| Bearings | Bush Type Bearing/ Anti Friction Roller Bearings | |||

Components

- Frame Assly

- Platens

- Hydraulic Cylinders

- Safety Switch Assly

- Hydraulic Power Unit

- Mould height assly

- Operator’s Control Desk

- Instrumentation Panel

- The HB Type presses have been designed specially for manufacturing and curing the bladders used in the AUBO, BOM and AUTOFORM presses.

- The control of the Hydraulic system included in the equipment is designed such that lower mould half carrying the uncured rubber approaches the upper mould half with high velocity during the first closing stage. Thereby, the total closing period is reduced to a minimum.

- In the beginning of the pressing operation the closing speed is stackened automatically in order to obtain slow and uniform compression of the uncured material. After lapse of the curing time, the press opens automatically and the bladders for AUBO and BOM presses are removed from the lower core plate.

Operation of Bladder Curing Press

- The bladder for AUTOFORM presses is detached by means of a pneumatic device which can be included in the delivery package on specific order.

- The two external mould portions and the core are cured by a direct steam connection.

- The press along with the hydraulic power unit are delivered in a “ready for connection” condition, excluding curing platens. The timer/PLC for automatic press opening after completion of the curing period as well as the steam/ condensate piping are normal features of supply.

Bladder Moulds:

The moulds are manufactured according to customers drawing using high grade steel.

Technical Data Sheet of Bladder Curing Press

Model |

HBV |

HB2 |

HB4 |

HB6 |

| Mould Range | Cycle & Motor-cycle | 11.00-20* | 12.00-24* | 18.00-24/25 |

| Maximum mould height (mm) | 250 | 750 | 850 | 1300 |

| Minimum mould height (mm) | 100 | 450** | 550** | 500 |

| Closing Pressure (tons) | 300 | 450 | 450 | 600 |

| Operation pressure (atm) | 250 | 250 | 250 | 180 |

| Electric power | 10 | 10 | 10 | 80 |

| Approx. weight of press (kgs) | 7000 | 9200 | 12000 | 38000 |

| Approx. closing speed H.P.(mm/min) | 100 | 66 | 66 | 36-336 |

| Approx. closing speed L.P.(mm/min) | 1000 | 1000 | 1000 | 1400-1700 |

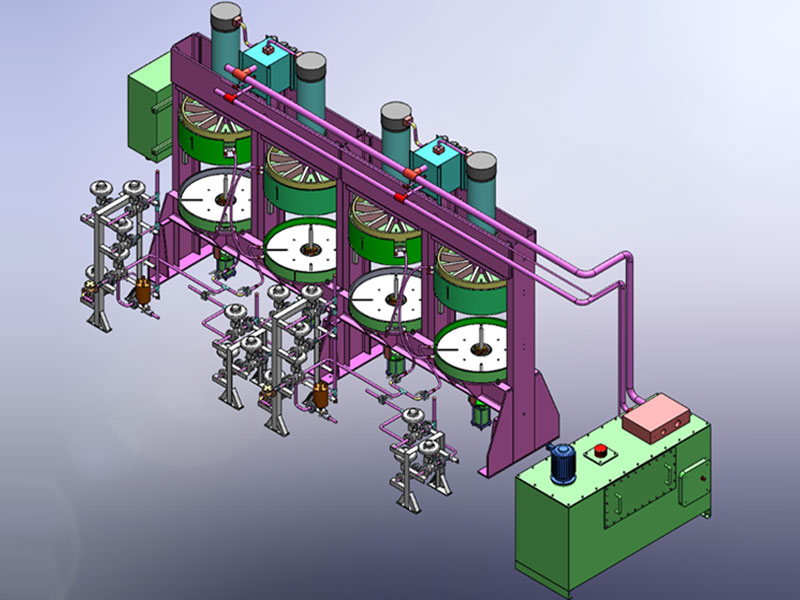

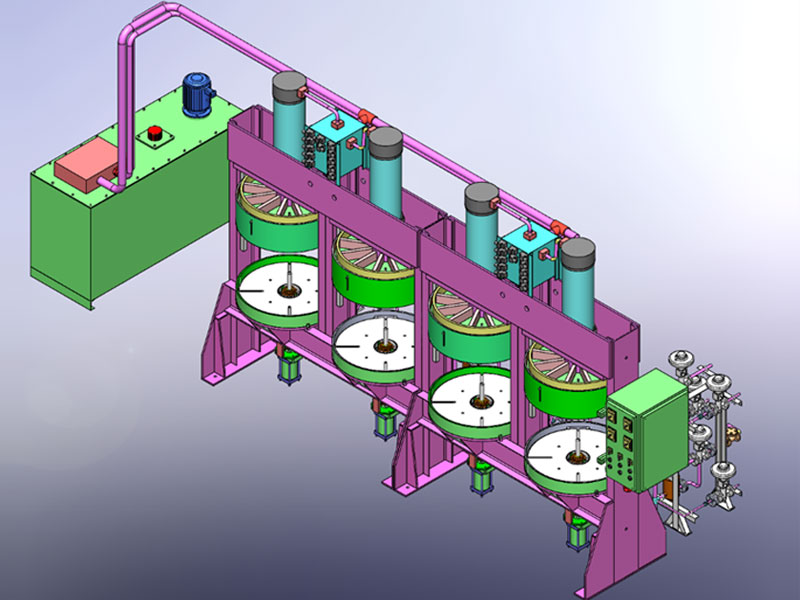

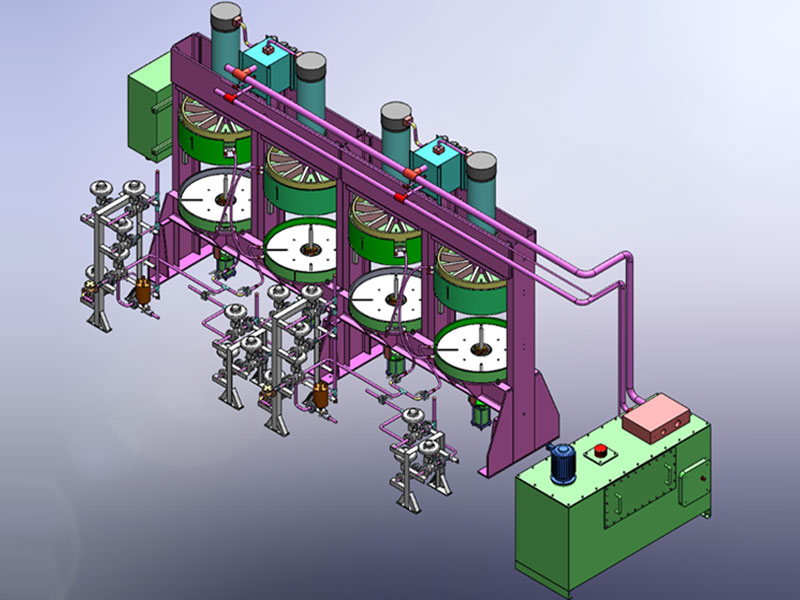

- AMCL designs and manufactures a complete range of Tube Curing Presses for all vehicle from scooters to heavy trucks & OTR.

- Great flexibility is built in to these machines each tube company’s design preferences in mind.

- Emphasis on safety precautions & interlocks.

- Both AC/DC Drive available.

- Centralized lubrication system.

- Timer/PLC available for auto cycle control.

General Description of Tube Curing Press

Design and Operation Features

- Tube curing presses require a drive enabling the mould halves to close within the shortest possible time in order to avoid premature curing of non-vulcanized and relatively thin material in the hot mould and to launch the curing process under internal pressure as quickly as possible. It takes 5.5 seconds to close the mould halves.

- Another important feature is revealed by opening and closing movement of the press. In opening the lower part of the press goes down by simultaneously tilting forward while the upper part remains fixed, thus providing a desk like loading and unloading position which is particularly advantageous in view of the flabby tubes having a relatively large diameter.

- The presses are delivered with or without curing platen. However, in the case of larger tubes, mould with steam jacket is generally used to obtain uniform curing. As the curing platen serves as mould fixation also, the upper curing platen is replaced by special mould retaining plate in mould with a steam jacket, while the lower mould half is fixed to the table. A central adjustment installation on the upper part of the press enables quick and uniform adjustment to the various mould heights.

Technical Data Sheet of Tube Curing Press

For moulds to be inserted in |

Model No. |

||||

EKK-S |

EKM-S |

EKO-S |

EK1-S |

EK2-S |

|

| Scooter tyre & Industrial tyre sizes | Motor cycle & passenger car tyre sizes | Passenger car & light truck tyre sizes | Truck tyre sizes | Truck tyre & Tractor tyre sizes | |

Maximum mould height without curing platens |

270 | 310 | 390 | 400 | 500 |

Minimum mould height without curing platens |

170 | 170 | 240 | 250 | 290 |

Maximum mould height with curing platens |

160 | 200 | 250 | - | - |

Minimum mould height with curing platens |

60 | 60 | 100 | - | - |