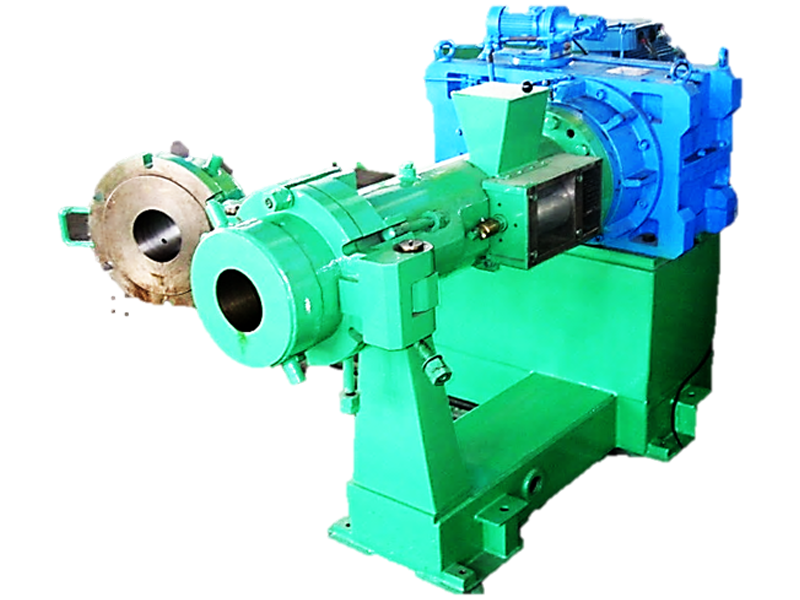

Hot Feed Extruder

Efficient and quality extrusions

AMCL’s range of Hot feed Extruders are evolved as a result of latest technology in collaboration with KOBE Machinery Co. Ltd. Japan and thorough insight of the Indian Tyre Industry’s requirements. Functionally featured and designed with robust manufacturing, the extruders perform in the most exacting conditions maximizing productivity.

Accessories |

Special thick wall steel pipe welded, spiral jacketed for heating and cooling fitted with bimetallic liner. |

Liner |

Nitriding steel, ground / honed finish. |

Screw |

Manufactured with Nickel chrome Molybdenum steel with right hand screw length of specified L/D ratio milled from solid stock with hardened flights and chrome plated for wear resistance. Screw is bored for hot water heating / cold water cooling and fitted with rotary joint and inner pipe. |

Hopper |

Suitable for feeding the material and spiral undercut for better feeding. |

Feed Roller |

Roll is driven through the gears powered by the reduction gear and water cooled through rotary joint. The gap is adjusted by bolts of scraper. |

Gear Box |

Helical gear box with lubrication pump. Output shaft provided with thrust bearing suitable for heavy thrust loading. |

Accessories |

Rotary joints, safety cover, guide roller, thermal indicator, lubrication pump, stop valves. |

Optional Items |

Tread / Tube die head assembly. Tread / Tube cooling line Temperature control unit ( 3 zone or 5 zone). |

Size |

4.5” | 6” | 8” | 10” |

Screw Flight |

Constant pitch flight | Double & Single flight, Variable Pitch | ||

Screw Size (Diameter) |

115 | 150 | 200 | 250 |

Screw Size (Length) |

518 | 790 | 1400 | 1500 |

L/D Ratio |

4.5:1 | 5:1 | 7:1 | 6:1 |

Screw Rpm |

40 rpm | 6-60 rpm | 6-60 rpm | 5-50 rpm |

Motor Power |

19 KW | 45 KW | 112 KW | 150 KW |

All Extruder are supplied with Three / Five zone Automatic Temperature (Optional) |

||||

Control system – As per customers’ requirements (Optional) |

||||