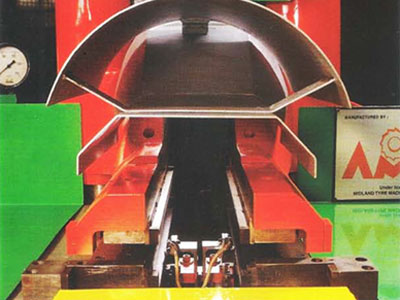

Tube Splicer

- A machine for splicing unvulcanized inner tubes

- AMCL-MIDLAND’s comprehensive range of Tube Splicing Machines are acclaimed as the most advanced systems and provide the end user with a range of advantages.

- Microprocessor based control system simplifies the complex sequences.

- Reliable ensuring consistent high strength tube joints & tubes durability.

- Precision knife guidance systems.

- State-of-the-art knife heat control.

- Solid state electrical control.

- Hydraulic adjustment of tube width.

Advance Features

- Dropping Knife Blades

- Precision knife guidance systems

- State-of-art knife heat control

- Solid state electrical control

- Hydraulic adjustment of tube width

- Knife cleaning facility

- Swash-type hydraulic pump

- Gravity scrap collection

Technical Data Sheet of Tube Splicer

Model |

900 |

1100 |

1200 |

Tube Flat Width Maximum |

200 mm | 500 mm | 750 mm |

Tube Flat Width Minimum |

20 mm | 120 mm | 450 mm |

Double Thickness Standard Special |

20 mm max./28 mm | 20 mm max./28 mm | 20 mm max./28 mm |

Maximum Unspliced Tube Length Standard Special |

800 mm/650 mm | 800 mm/650 mm | 1200 mm |

Machine Height (Approx) |

1900 mm | 1900 mm | 2300 mm |

Machine Width (Approx) |

1600 mm | 1600 mm | 2100 mm |

Machine Depth (Approx) |

1600 mm | 1600 mm | 1700 mm |

Nett Weight (Approx) |

2500 kgs | 2500 kgs | 5000 kgs |

Tubes Per Cycle |

Two | One | One |

Approximate Machine Cycle Time |

25-40 Seconds | 20-35 Seconds | 30-55 Seconds |

Electrical Supply |

6.5 kW at 415V, 3 Phase, 50 Hertz | ||